Expert Design, Manufacture, and Installation

The Yosmite Water-Cooled Burner Valve replaces conventional burner doors, changing stoves from "gas" to "blast" in 10 seconds, ensuring safety, and fitting various installations without costly foundations.

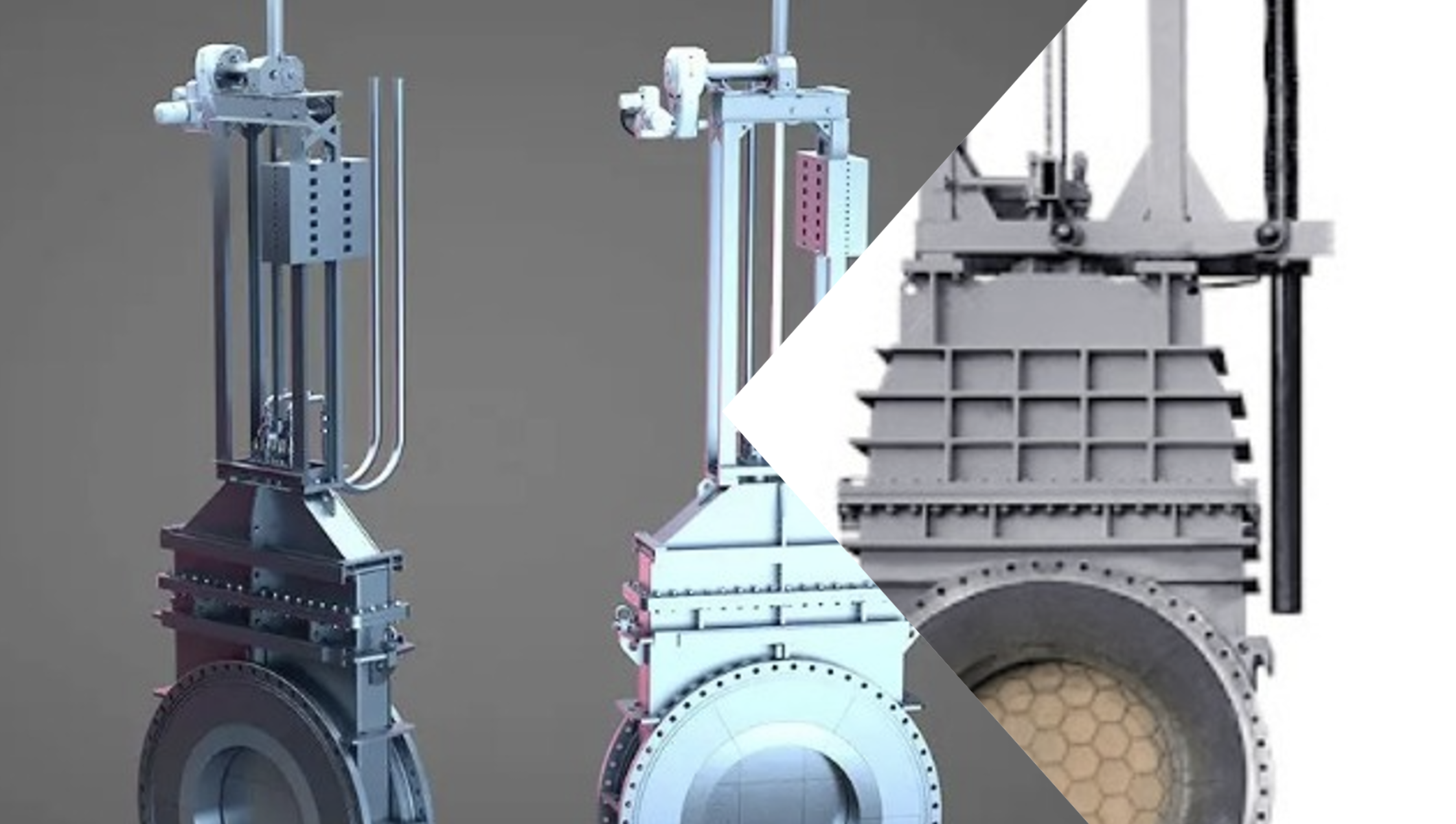

The Yosmite Burner Valve features a water-cooled disc that moves vertically within a water-cooled valve body and bonnet, ensuring smooth seating and release. The disc is flange-mounted to a hollow ground stainless steel stem attached to a manifold. This configuration provides durability and efficient operation and link system with bearings.

The Yosmite "Power Drive" is designed for heavy-duty use and includes built-in torque protection, motor overload relays, and externally mounted limit switches. The actuator is interchangeable with other similar actuators, making it versatile and adaptable to various applications.