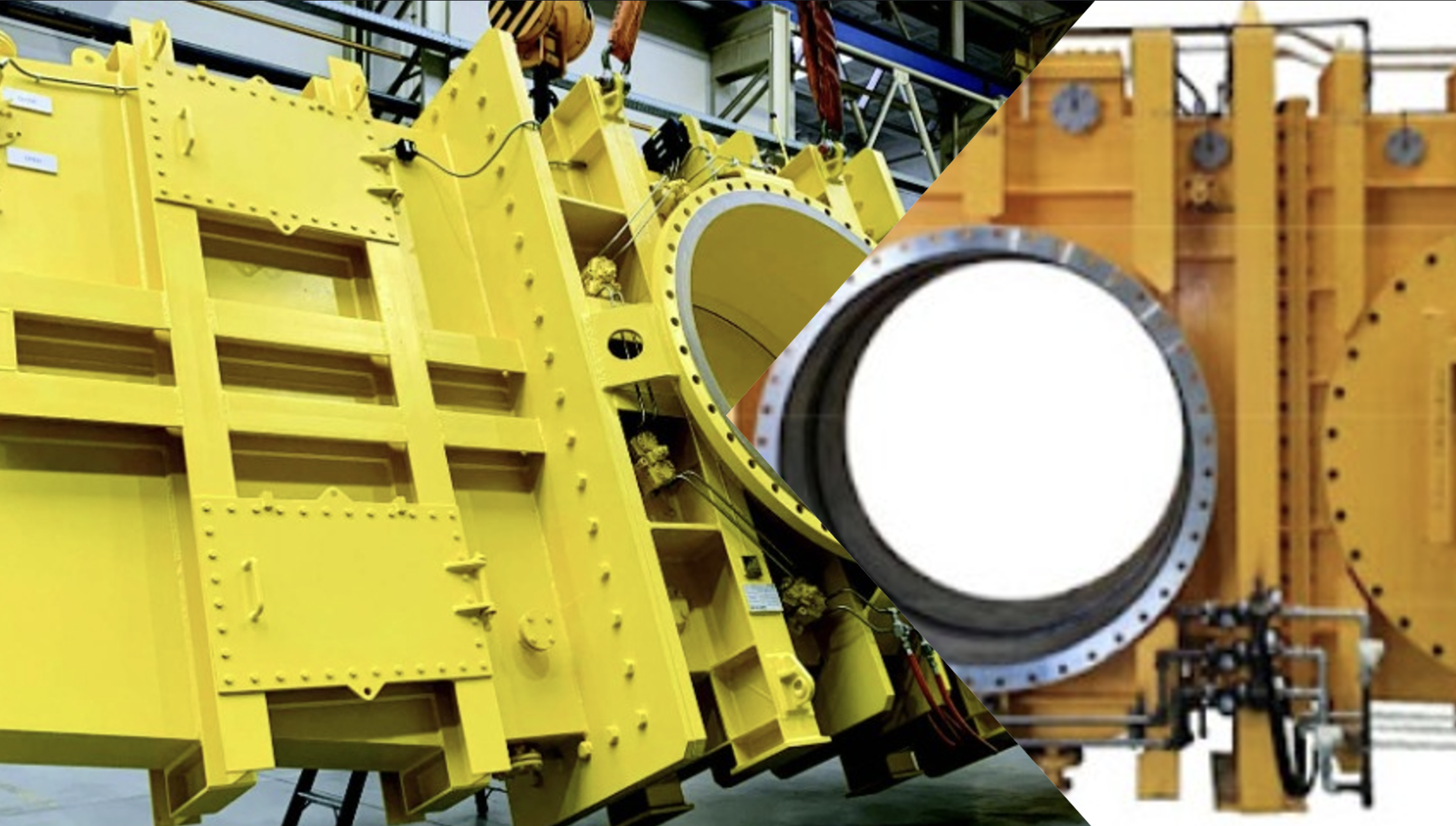

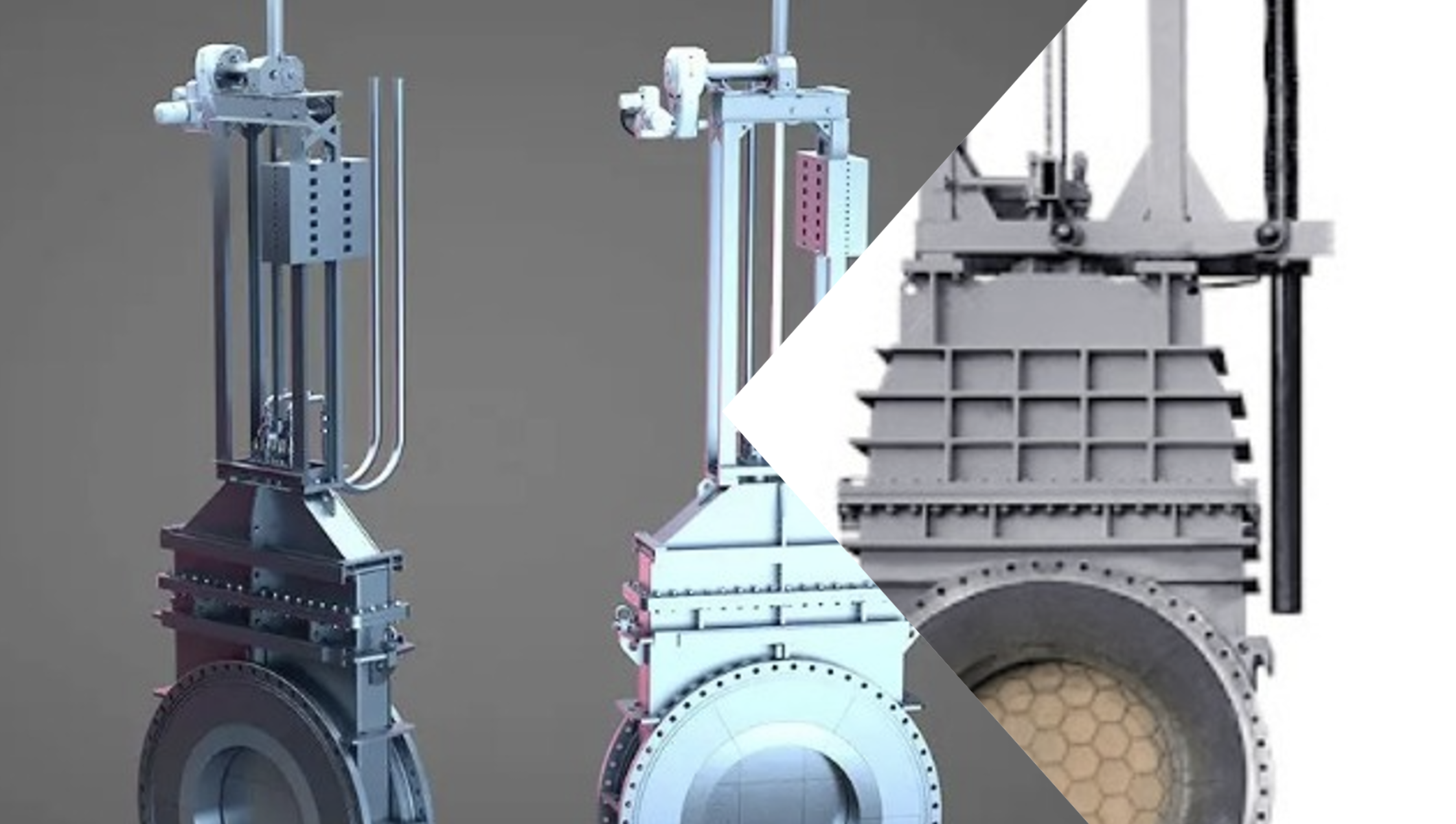

Blast Furnace Burner Valves

Experience quick and safe stove changes from "gas" to "blast" with Yosmite Engineering's Water-Cooled Burner Valve. Replacing conventional burner doors, it opens or closes in just 10 seconds for a swift transition.

Key Features and Advanced Design:

Yosmite Engineering's Water-Cooled Burner Valve operates swiftly, opening or closing in just 10 seconds for stove changes. It ensures safety with advanced electromechanical methods and motor protection.

Compact and self-supporting, it needs minimal space and no costly foundations, available in sizes from 30" to 72". Designed for 50 psi working pressure and rated for 2800°F flame impingement, flange-mounted to the disc, connects to a manifold for precise movement.