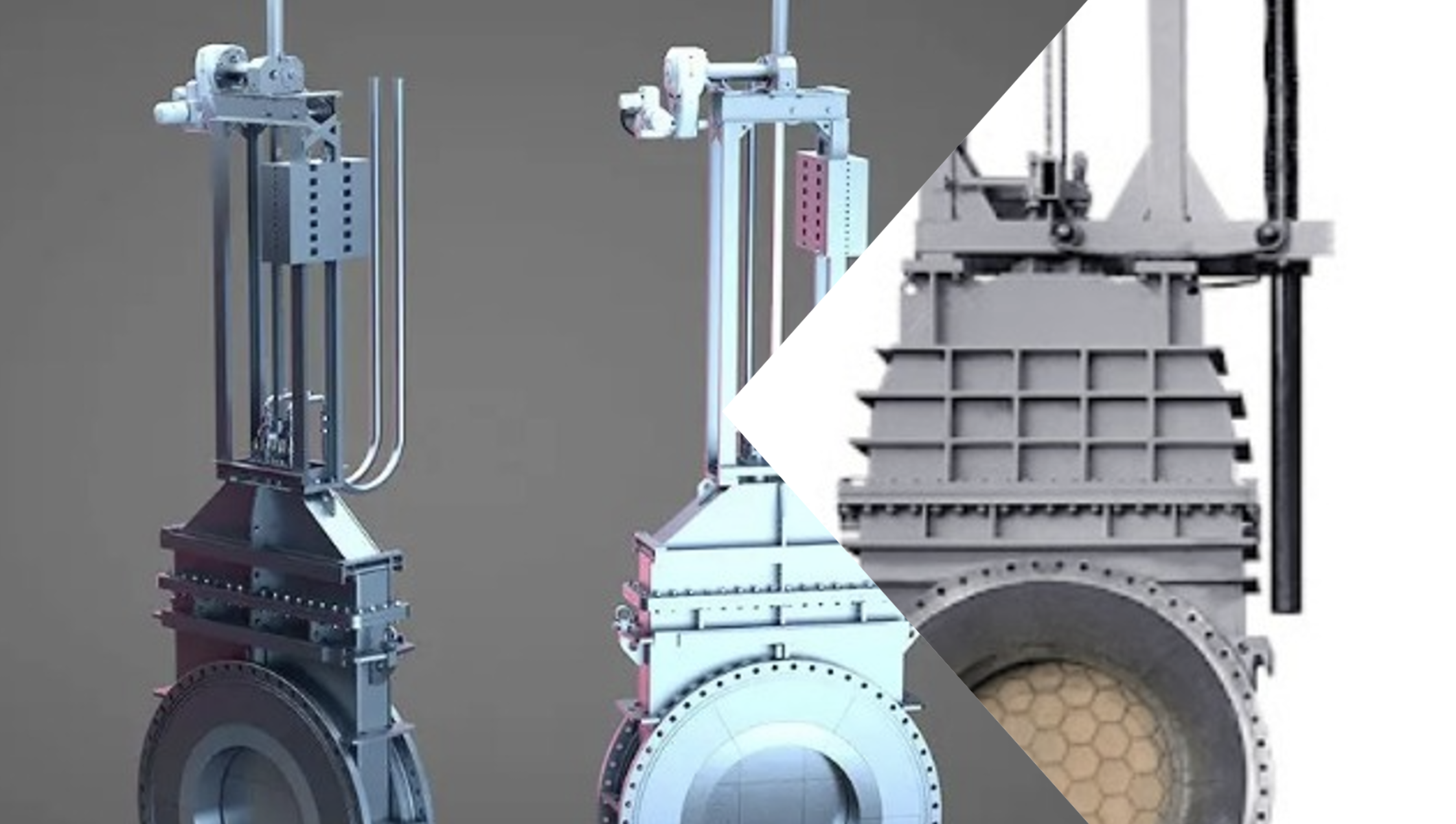

Blast Furnace Hot Blast Valve

The Blast Furnace Hot Blast Valve is engineered for high-performance reliability in critical blast furnace applications.

Designed with robust construction, it ensures absolute tight shut-off and dependable operation under extreme temperatures. Its simplified design enhances ease of use and facilitates cost-effective maintenance, making it an economical choice for industrial settings.

This valve is versatile, suitable for vertical operation in horizontal mains and adaptable for horizontal operation in vertical mains. It provides secure separation on each side of the goggle plate to prevent gas leakage, redirecting any potential leaks safely to the atmosphere. Ideal for blast furnaces, basic oxygen converters, open hearths, and other gas mains, it stands out for its durability and efficiency in demanding industrial environments.